Senior Hydraulic Engineer

Michael Rickert

Insight

Liveability and sustainability are the words on everyone’s lips. Cities are being re-imagined. Buildings are changing. Designers are at the forefront of this change.

‘Net-zero’ is no longer a buzzword being thrown around by politicians and scientists. Net-zero is here, and buildings are under the microscope. Limiting carbon emissions via sustainable building practices, removing non-renewables and carbon offsets are essential to the design of the built environment.

Hydraulic services design (or ‘plumbing’ for lack of a better word) has been relatively unchanged in Australia for many years. So how can a service that remains somewhat constant move towards a more sustainable future, how can smart hydraulic services design realise the net-zero dream?

Most options for a hydraulic services designer are limited, PVC and metal pipework for example have not changed in a long time, but one avenue for change is within the hot water system, in particular the hot water plant.

Gone are the days of electric storage vs gas storage as the only options, and soon the days of gas-powered plants will end altogether. The industry has already seen a shift to air-to-water and water-to-water heat pumps which replace the gas hungry and high electric load storage plants. Heat pumps cost approx. 25% less to operate when compared to a traditional electric storage heater and can offer a coefficient of performance of 4.0 when heating which saves on energy, making it a more sustainable option.

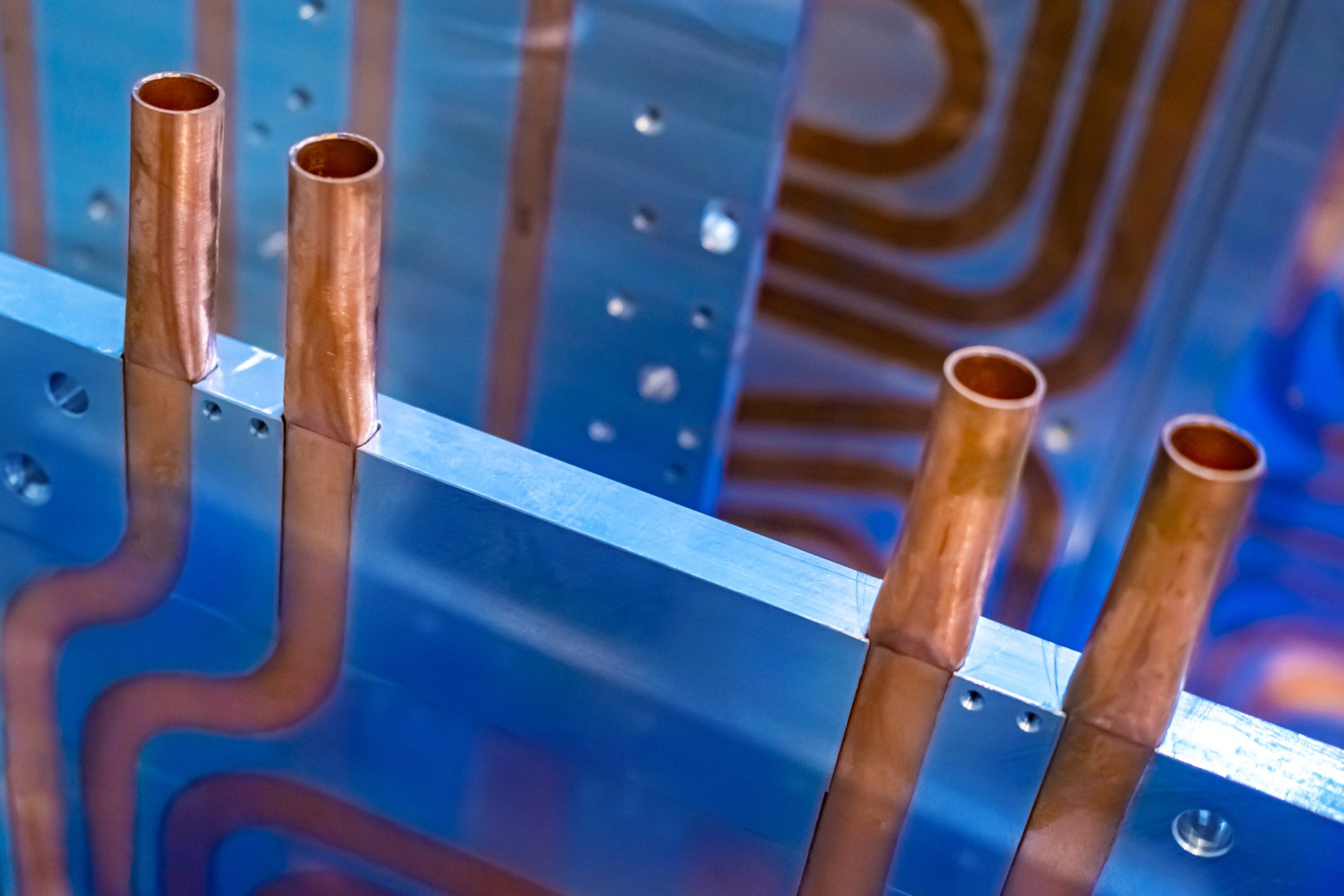

Where heat pumps are the ‘present’, plate heat exchangers are the future. Plate heat exchangers allow for a non-contact water-to-water heat exchange between almost any heated fluid system to boost the temperature of the hot water system. Usually installed as a ‘preheat’, where the incoming water temperature to the hot water plant is elevated to minimize the overall energy input to the hot water plant, this installation can exchange redundant heat from geothermal plants, mechanical heated water pipework and other sources of heated liquid.

Further options for heat exchange in Australia may not be far off with Europe leading the way in installing brine cooled PV panels where the heated brine could be used to exchange heat with the hydraulic hot water system.

Utilizing a plate heat exchanger to preheat the incoming water prior to a heat pump plant could be the way of the future for many buildings. Eliminating gas and reducing electric load, thus producing a more sustainable option for building hot water systems.

The future of hydraulic services design can be as sustainable as we make it. Allowing for sustainable options in design is the first step, even within a service that has seen little recent change.

“Gone are the days of electric storage vs gas storage as the only options, and soon the days of gas-powered plants will end altogether.”

P: +61 2 8203 5447

M: +61 0405 347 061

E: [email protected]